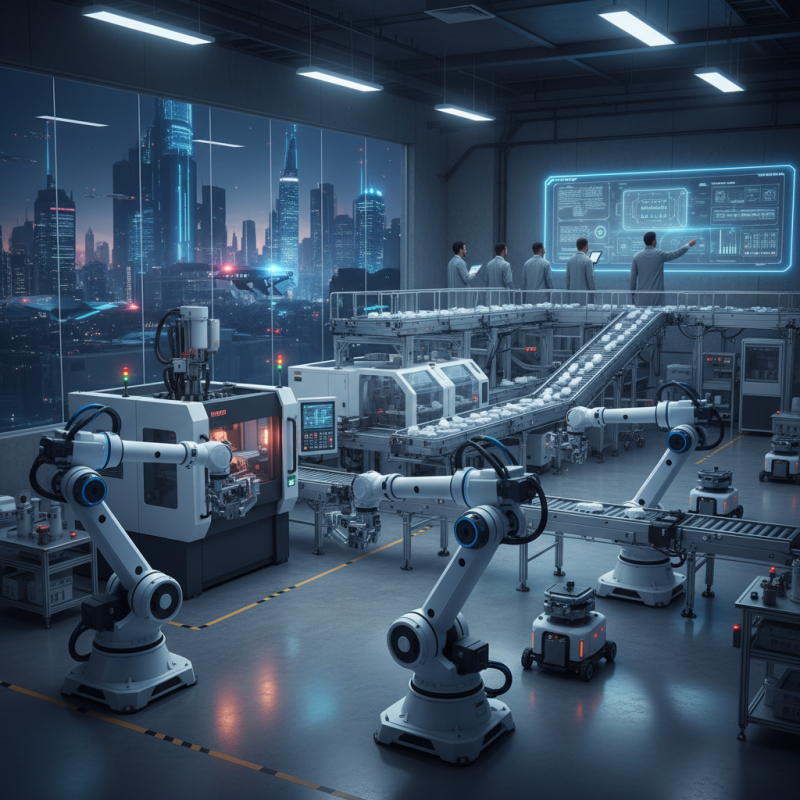

The injection molding industry is on the rise. According to a recent report by MarketsandMarkets, the global market for Injection Machine Robots is expected to reach $3.8 billion by 2026, growing at a CAGR of 8.5%. This growth reflects advancements in automation and efficiency in manufacturing. Industry experts like Dr. Robert Chang emphasize the importance of innovation. He stated, “Injection Machine Robots are transforming production lines and enhancing precision in ways we never imagined.”

As manufacturers seek to improve productivity, the adoption of Injection Machine Robots is increasing. These robots not only reduce labor costs but also improve quality and speed. However, challenges remain. Integration with existing systems can be complex. Additionally, training for effective human-robot collaboration is necessary. This means the path forward isn't entirely smooth.

The future of Injection Machine Robots seems promising but calls for careful consideration. Companies must navigate technological and operational hurdles. Reflection on these challenges can lead to better solutions. Such a mindset will ultimately drive the injection molding industry to new heights.

Injection machine robots play a pivotal role in modern manufacturing. These automated systems efficiently handle various tasks, enhancing productivity and precision. Their ability to operate round the clock without fatigue significantly boosts output. Operators often marvel at the intricate designs these robots can achieve with minimal errors. The precision is astounding, yet occasional misalignments happen, prompting constant adjustments.

Hygiene is vital in many industries, especially food and medical manufacturing. Here, injection machine robots minimize human contact, reducing contamination risks. However, human oversight remains essential to ensure safety. Training staff to work alongside these robots is crucial. Challenges arise from integrating new technologies into traditional workflows. Companies often struggle with adapting their staff to these advances.

Manufacturers appreciate the cost-effectiveness of injection robots. They can reduce labor costs while increasing production speed. Yet, the upfront investment is significant. Firms must weigh these factors carefully. Reflecting on the balance between automation and human involvement is necessary. While robots enhance efficiency, the human element cannot be entirely eliminated. All these aspects underline the ongoing evolution in the use of injection machine robots.

When considering injection machine robots, it's crucial to focus on important features. One key aspect is precision. A robot that accurately controls injection volume can significantly reduce waste and improve product quality. Look for models equipped with advanced sensors and controls to enhance this aspect.

Another vital feature is flexibility. Machines that can handle various materials and mold types are ideal. This allows for quick changes between production runs. Additionally, robots should have user-friendly interfaces. A complex interface can lead to errors and waste valuable time.

Lastly, maintainability matters. Robots should be easy to service and repair. Frequent downtime can disrupt production. It's essential to assess how accessible parts are and whether the manufacturer offers sufficient support. Despite the advances in technology, some robots still face challenges. High initial costs and the need for skilled operators are common concerns. These factors require careful consideration before making a decision.

| Model | Type | Payload Capacity (kg) | Speed (m/s) | Precision (mm) | Key Feature |

|---|---|---|---|---|---|

| Model A | Electric | 100 | 1.2 | 0.01 | Energy Efficient |

| Model B | Hydraulic | 200 | 0.8 | 0.05 | High Speed |

| Model C | Hybrid | 150 | 1.0 | 0.02 | Compact Design |

| Model D | Electric | 120 | 1.5 | 0.03 | User-Friendly Interface |

| Model E | Hydraulic | 250 | 0.6 | 0.04 | Heavy Duty |

| Model F | Hybrid | 180 | 1.1 | 0.02 | Multi-Functional |

| Model G | Electric | 110 | 1.3 | 0.01 | Environmentally Friendly |

| Model H | Hydraulic | 230 | 0.7 | 0.03 | High Precision |

| Model I | Electric | 140 | 1.4 | 0.02 | Smart Technology |

| Model J | Hybrid | 160 | 1.0 | 0.03 | Versatile Applications |

Injection molding robots have become essential in modern manufacturing. They automate processes, improve efficiency, and enhance product quality. These machines operate with precision. Their ability to work tirelessly makes them invaluable. When considering an injection machine robot, several features demand attention.

Tips: Look for flexibility. Robots should adapt to different materials and shapes. Efficiency matters. A faster robot can enhance production rates. Additionally, check for ease of integration. The robot should seamlessly fit into existing workflows. This might require some trial and error.

Understanding the technology is crucial. Different robots suit various applications. Some might excel in speed but lack precision. Others could be slower but offer better accuracy. It's important to find a balance that fits your needs. Don't overlook maintenance either. Regular checks are vital for long-term performance.

Each robot comes with unique specifications. Compare them carefully. Focus not just on features but also user feedback. Real experiences help gauge reliability. Some products may promise much but deliver less. Critical assessment can save time and resources. Choose wisely.

In today's manufacturing landscape, injection machine robots play a vital role in ensuring efficiency. Each model brings unique strengths and weaknesses. Some machines excel in speed, while others prioritize precision. A thorough analysis of their performance is key to making informed choices.

Consider speed versus accuracy. Some models produce parts rapidly but may sacrifice detail. This trade-off impacts the overall quality of production. Crafting a well-made product is essential. Machines that focus solely on speed often require adjustments later, leading to delays. Efficiency can vary by design, even among leading contenders.

Cost-effectiveness also matters. While high-performance robots are attractive, initial expenditures can be daunting. A machine may appear efficient but could have hidden operational costs. Reflecting on long-term gains is necessary. Manufacturers must analyze maintenance needs and downtime effectively. Balancing these factors is crucial for achieving optimal results in injection molding applications.

The future of injection machine robotics is undeniably exciting. Recent studies predict significant growth in this sector, with an anticipated increase of over 20% in market size by 2025. This surge is driven by advancements in automation and AI integration. Robots are becoming more efficient, capable of performing complex tasks quickly.

With the rise of Industry 4.0, manufacturers are exploring smart solutions. These robots can learn from their surroundings and adapt their processes. For example, the introduction of vision systems allows robots to identify defects in real time, improving quality control. However, the implementation of such technology may come with challenges, like the need for skilled operators who can manage these sophisticated machines.

Moreover, sustainability is shaping future innovations. Robots are now designed to work with biodegradable materials. They aim to reduce waste and energy consumption. Yet, not all systems are optimized for eco-friendly practices. There is a real need for ongoing research and development to bridge this gap. The advancements in injection machine robotics depend on striking a balance between technological progress and environmental responsibility.

Rob was always very honest and upfront about everything and took the time to explain everything I needed.

“highly recommended. They provided us with a great storage container with ontime services.”

“Bought a used container, its perfect, no leaks and in good condition.”

“Good service and prompt delivery. A great option for temporary storage at a decent price.”

Join our mailing list to get the latest storage container inventory and offers