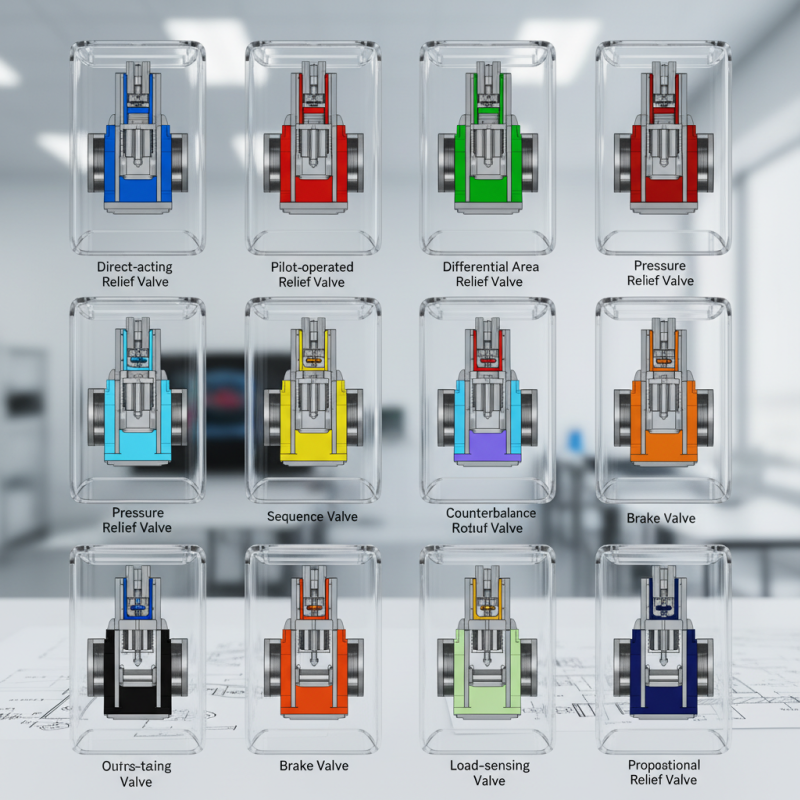

Top 10 Overflow Valve Block Types and Their Functions?

In the world of hydraulic systems, the Overflow Valve Block plays a crucial role in maintaining optimal performance. According to industry expert Dr. James Holloway, “Understanding the different types of Overflow Valve Blocks is vital for any engineer.” This statement underscores the importance of recognizing how each block type functions.

Overflow Valve Blocks come in various designs, each serving specific purposes. They ensure safety by preventing over-pressurization. However, not all blocks are created equal. Differences in design can lead to inefficiencies if not understood properly. Engineers must consider these factors for effective applications.

The choice of an Overflow Valve Block can impact the entire hydraulic system. Each type has its unique advantages and limitations. Misunderstanding these can cause malfunctions or safety hazards. Engineers should strive to grasp these nuances for better system reliability. Exploring the top 10 types offers insights for optimizing performance and safety.

Overview of Overflow Valves and Their Importance in Fluid Systems

Overflow valves play a crucial role in fluid systems. They help maintain pressure and protect components from damage. These valves are essential for preventing dangerous situations caused by hydraulic pressure buildup. When pressure exceeds safe limits, the overflow valve activates. It redirects fluid, ensuring safe operation.

Many types of overflow valves exist. Each serves a unique purpose in different applications. Some are simple and cost-effective, while others are more complex. For instance, pilot-operated overflow valves offer precise control. They can adjust pressure levels accurately. However, they may require more maintenance and monitoring.

Understanding the importance of these valves can be challenging. Every fluid system has specific needs. What works for one might not suit another. Designers and engineers must consider various factors: flow rate, fluid type, and system configuration. Missing these details can lead to inefficiencies or failures. Constant reevaluation of the system is crucial for optimal performance.

Types of Overflow Valve Blocks and Their Distinct Functionalities

Overflow valve blocks are essential in hydraulic systems. They help control pressure and prevent system failures. Various types occur, each serving unique functions. For instance, the pilot-operated overflow valve block is sensitive and reacts quickly to pressure changes. Its design improves system responsiveness, but calibration can be challenging.

Another common type is the direct-acting overflow valve block. This type is simple and effective in many applications. It provides reliable pressure control but may exhibit faster wear rates, demanding regular maintenance. A report from the Hydraulic Institute reveals that a well-maintained valve can extend the system's lifespan by up to 30%.

Further, anti-cavitation overflow valve blocks are specialized for applications prone to cavitation. They ensure smooth operation by minimizing turbulence. However, they may not be compatible with all systems. The choice of overflow valve blocks should align with specific system requirements. Misalignment can lead to inefficiencies and costly repairs down the line.

Key Components of Overflow Valve Blocks and Their Roles

Overflow valve blocks play a crucial role in hydraulic systems. They protect equipment from excessive pressure. Understanding their key components can enhance system effectiveness.

The primary component of an overflow valve block is the valve itself. This valve regulates fluid flow and prevents pressure spikes. Sometimes, the valve can become jammed, leading to inefficient performance. Regular maintenance is essential to ensure smooth operation.

Another critical part is the pressure regulating spring. This spring adjusts the opening pressure of the valve. If the spring is worn or damaged, it may not function correctly. Replacing a faulty spring can improve system reliability.

Tips: Check for leaks regularly. Small leaks can lead to bigger issues over time. Keep valves clean to avoid contamination. A dirty valve can hinder performance.

Lastly, consider the inlet and outlet ports. These should align correctly for optimal flow. Misalignments can cause back pressure, affecting the entire system. Proper installation reduces headaches later.

Factors to Consider When Choosing Overflow Valve Block Types

When choosing an overflow valve block type, several factors come into play. One key consideration is the pressure rating. Ensure the valve can handle the system's maximum pressure. Understanding the flow rate is vital too. The right valve allows for efficient fluid movement. Too small a valve causes back pressure and can lead to failures.

Material selection is another important aspect. Different materials affect durability and corrosion resistance. For instance, stainless steel offers high resistance to rust, while plastic might be lighter and cheaper. However, plastic may not withstand high pressure.

Lastly, consider installation ease and maintenance. Some designs require specialized tools. Complexity can lead to errors during installation. Regular maintenance ensures long-lasting performance. Neglect could result in costly repairs down the line. Always reflect on these elements before making a decision.

Maintenance Tips for Ensuring Optimal Performance of Overflow Valves

Overflow valves play a crucial role in hydraulic and pneumatic systems. Regular maintenance ensures they function properly. A well-maintained valve prevents system failures and reduces downtime. Check for leaks regularly. Even small leaks can lead to significant issues over time. Inspect the seals and gaskets; wear and tear may go unnoticed until it’s too late.

Cleaning is vital. Contaminants can clog valves, affecting performance. Use appropriate cleaning solutions that won’t damage components. Rinse thoroughly to avoid residue buildup. Monitor the valve's response during operation. It should open and close smoothly. If you notice any hesitance, it’s time to investigate further.

Remember, sometimes it’s easy to overlook minor issues. Don’t let small problems escalate. Document your maintenance activities. This will help track performance trends. Regular assessments can reveal patterns, guiding future improvements. An effective maintenance routine goes beyond basic cleaning; it involves understanding how your system functions.

Top 10 Overflow Valve Block Types and Their Functions

This chart illustrates the distribution of different types of overflow valve blocks and their respective functions in various systems, helping to identify the most commonly used types and their significance in maintaining system integrity.