How to Choose the Right Position Sensor for Your Application?

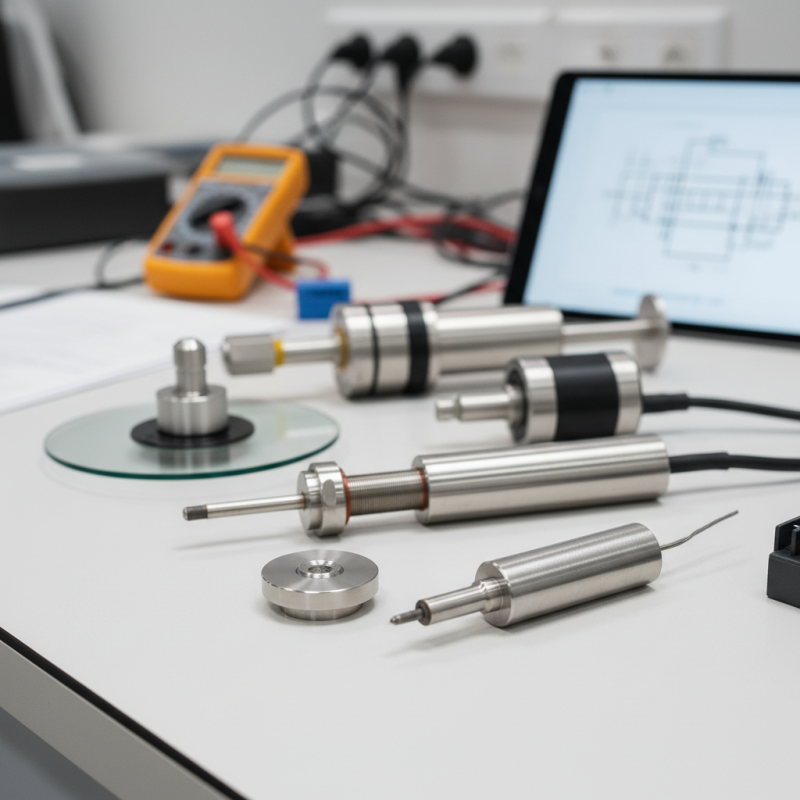

Choosing the right Position Sensor is crucial for your application. These devices are vital in various industries, from robotics to automation. They determine the exact location of an object, providing essential data for monitoring and control.

Position sensors come in many types and technologies, each with unique advantages and challenges. For instance, capacitive sensors offer high accuracy but may struggle in dirty environments. Conversely, magnetic sensors excel in harsh conditions but may not provide the precision required for critical applications.

When selecting a position sensor, it is essential to consider the specific needs of your project. Is the environment hostile? What level of accuracy do you require? Explore your options carefully. Reflection on your choices can lead to better decision-making. The right position sensor can greatly enhance the performance of your system, while the wrong choice can lead to frustration and failures.

Types of Position Sensors and Their Applications

Position sensors play a crucial role in various industries, including automation, robotics, and aerospace. The choice of sensor often depends on specific needs and applications. Common types include resistive, capacitive, inductive, and optical sensors. According to a market research report, the global position sensor market is projected to reach $5.7 billion by 2025, driven by advancements in smart technologies.

Each type offers unique advantages. For example, resistive sensors are cost-effective and suitable for simple applications. Capacitive sensors excel in detecting non-metallic objects. Inductive sensors are ideal for challenging environments, like those with dirt or moisture. Optical sensors can provide very high precision but may be affected by ambient light. It’s essential to evaluate the environment and required precision before making a decision.

However, not all sensors fit every application. For instance, excessive noise can interfere with signal integrity. Many professionals overlook the required sensitivity, leading to inaccurate readings. It’s also common to underestimate installation challenges. Balancing these aspects is key to effective sensor selection. Understanding your specific situation can save time and resources in the long run.

Key Factors to Consider When Selecting a Position Sensor

When selecting a position sensor, several key factors influence your decision. The application is critical. For instance, harsh environments may require rugged sensors. Temperature, humidity, and exposure to chemicals can all play a role. Sensors need to withstand these conditions to ensure accuracy and longevity.

Another important factor is the measurement range. Consider how far the sensor will detect position changes. Some applications only require a small range, while others need extensive coverage. This affects which technology will work best. For example, linear sensors are ideal for specific measurements but may not suit every situation.

Finally, output type matters. Analog and digital signals can both serve different needs. Assess what your system can handle well. Calibrate your choice based on compatibility with existing equipment. Reflecting on these factors helps to narrow down options. Still, some who rush this process can make costly mistakes.

Understanding Sensor Specifications and Performance Metrics

Choosing the right position sensor involves understanding its specifications and performance metrics. Each sensor has unique characteristics. These include precision, response time, and range. Precision is critical for applications requiring accurate measurements. In some cases, higher precision may lead to increased costs. This trade-off needs careful consideration.

Response time is another vital metric. It determines how quickly the sensor reacts to changes. For dynamic applications, a fast response time is crucial. However, not all sensors excel in this area. Some might lag, affecting overall performance. It is essential to assess your application's needs before making a decision.

Moreover, consider the sensor's environmental ratings. Some sensors are designed for harsh environments, while others are suited for indoor use. The temperature range and humidity levels play a role here. Inadequate specifications can result in sensor failure over time. Reflection on these aspects will help ensure you choose a suitable sensor.

Sensor Performance Metrics Comparison

Evaluating Environmental Conditions for Sensor Deployment

When selecting a position sensor, understanding environmental conditions is essential. Sensors often face various challenges, including temperature, humidity, and dust. These factors can affect sensor performance. For example, extreme temperatures may cause failure or inaccurate readings. Sensor location is as crucial as sensor type.

Tip: Assess the temperature range of the environment. Ensure sensors can reliably operate within these limits.

High humidity can lead to corrosion or short circuits. For outdoor applications, water ingress protection is vital. Sometimes, sensors may need additional housing to shield against moisture. Dust and particulate matter can clog sensors, impeding their function.

Tip: Consider using sealed or robust housings for sensors deployed in harsh conditions. Regular maintenance may also be necessary to ensure continued reliability.

In some situations, it’s easy to overlook minor environmental factors. They can have a significant impact on reliability. Monitor conditions periodically. This can help in recognizing patterns that may affect sensor accuracy. The environment is dynamic; adapt your sensor choice accordingly.

Comparing Cost and Value for Different Position Sensor Options

When selecting a position sensor, cost and value are crucial elements to consider. Position sensors vary significantly in price, but the cheapest option isn’t always the best choice. According to recent industry reports, high-quality sensors often deliver better long-term reliability. For instance, investing in a more expensive magnetostrictive sensor can reduce maintenance costs by up to 30% over time.

Tips: Always assess the total cost of ownership. Think about installation, maintenance, and replacement. These hidden costs can quickly add up.

Performance metrics also play a vital role in value assessment. A study from a leading automation research firm shows that sensors with higher accuracy can improve system efficiency by 15%. However, this comes at a higher initial cost. Companies must weigh the trade-off between upfront expenses and long-term gains.

Tips: Consider the application requirements carefully. A sensor that seems more affordable may underperform, leading to operational hiccups.

Evaluating different position sensor technologies helps clarify choices. Capacitive sensors are generally more affordable but may lack precision. Always remember that cost should not be the lone decision factor. Balancing performance with budget constraints can lead to better outcomes.

How to Choose the Right Position Sensor for Your Application? - Comparing Cost and Value for Different Position Sensor Options

| Sensor Type | Accuracy (%) | Range (mm) | Response Time (ms) | Cost ($) | Value Rating (1-5) |

| Potentiometer | 1.5 | 0-100 | 10 | 15 | 3 |

| Hall Effect | 0.5 | 0-200 | 5 | 25 | 4 |

| Linear Variable Differential Transformer (LVDT) | 0.1 | 0-500 | 1 | 200 | 5 |

| Optical Encoder | 0.05 | 0-300 | 2 | 150 | 5 |

| Magnetic Encoder | 0.1 | 0-250 | 3 | 80 | 4 |